micro indentation hardness tester|micro indentation hardness : advice Ideal for a production facility or a research lab, our LM Series of Microindentation Hardness Testing Systems offers a variety of models (including analog and digital) with advanced features that can be tailored to meet your unique . Sterilization cycle development is an important part of both the autoclave procurement and validation processes. Learn how it works and why it matters.

{plog:ftitle_list}

$498.00

what is indentation hardness

Ideal for a production facility or a research lab, our LM Series of Microindentation Hardness Testing Systems offers a variety of models (including analog and digital) with advanced features that can be tailored to meet your unique .Microindentation hardness testing (or microhardness testing) is a method for measuring the hardness of a material on a microscopic scale. A precision diamond indenter is impressed into the material at loads from a few grams to 1 kilogram. The impression length, measured microscopically, and the test load are used to calculate a hardness value. .

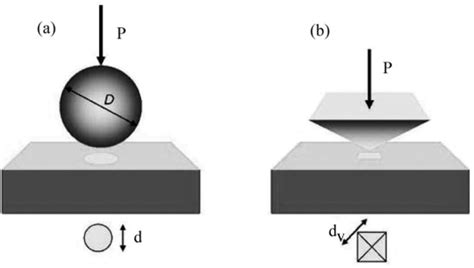

spherical indentation hardness

CM Series Micro Hardness Testers utilize advanced technology for incredibly accurate test results. And for optimum flexibility, combine the CM Tester with our available ARS Software, for a complete automated testing system. Request a .

The Vickers hardness test is often regarded as easier to use than other hardness tests: The process can be performed on a universal or micro hardness tester; the required calculations are independent of the size of the indenter; and the .

Nano, micro indentation and scratch tests on same platform using fast exchange heads. The Surface Mechanical Tester SMT-5000 is a versatile instrument. It merges the ability to measure mechanical properties, such as hardness, modulus, scratch adhesion, film thickness, in addition to surface roughness and many others.

Microindentation hardness testing is a very valuable tool for the materials engineer, but it must be used with care and full understanding of potential problems. The purpose of microindentation hardness testing is to study fine scale changes in hardness, either intentional or accidental. The technique is also commonly known as microhardness .

Vickers/Knoop Micro-Hardness Tester with Test & Measurement software Windows 10 "N-Sure" including Auto-Measurement module Test Loads: 10, 25, 50, 100, 200, 300, 500, 1000 gf suitable . Compare this product Remove from comparison tool. See the other products Metkon Instruments Inc. 5.4 Microindentation hardness testing is generally performed to quantify variations in hardness that occur over small distances. To determine these differences requires a very small physical indentation. Testers that create indents at very low test forces must be carefully constructed to accurately apply the test forces exactly at the desired location and must have a .

The Micro Combi Tester (MCT³) is a universal measurement head for full mechanical characterization of coatings and bulk samples. The unique wide load range of this instrument allows the determination of adhesion, scratch resistance, hardness, elastic modulus, friction, and wear for a wide range of samples.

microindent test hardness

There are only two micro-indentation testers: Vickers hardness test and Knoop hardness test (9, 26) Which are suitable and practical methods for evaluating surface changes of dental hard tissues . What is ASTM E384-22?. The test method in ASTM E384-22 covers determination of the microindentation hardness of materials, which involves using a calibrated machine to force a diamond indenter of specific geometry into the surface of the material being evaluated. This test method is largely applicable to heat treaters, metallographers, metallurgists, material .The Wilson VH1102 and 1202 Micro Hardness testers provide dependable solutions for precise micro hardness testing in quality control and metallurgical research. Skip to content +1 847-295-6500; [email protected]; Mon - Fri: 8am - 4pm CST; About Contact Products Close Products Open Products. 5.4 Microindentation hardness testing is generally performed to quantify variations in hardness that occur over small distances. To determine these differences requires a very small physical indentation. Testers that create indents at very low test forces must be carefully constructed to accurately apply the test forces exactly at the desired location and must have a .

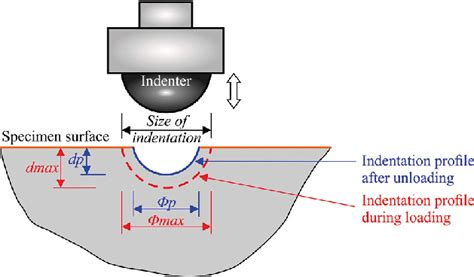

Instrumented indentation test, also known as nanoindentation test, has been widely used to evaluate the local indentation hardness of materials at the nano- and micro-scales for academic and industrial purposes; it has been frequently compared with the Vickers hardness (HV) test used on larger scales [].A considerable number of studies have investigated the .The NHT³ Nanoindentation tester is designed for measuring hardness, elastic modulus, creep, and other surface properties from the nanometer to the micrometer scale. Its force ranges from 0.1 mN to 500 mN for maximum versatility. With the unique top surface referencing technique, an instrumented indentation measurement can be made immediately . Metallography and is the direct responsibility of Subcommittee E04.05 on Micro-indentation Hardness Testing. With this revision the test method was expanded to include the requirements previously deÞned in E28.92, Standard Test Method for Vickers Hardness Testing of Metallic Material that was under the jurisdiction of E28.06

The DuraVision universal hardness testers for standard load ranges of 0.3-250 kgf or 3-3,000 kgf can be used for Vickers, Knoop, Brinell, and Rockwell tests, as well as for carbon and plastics testing.All methods are covered by the ISO .

LECO offers a wide selection of hardness testing systems to match any application or budget. Choose from manual and automatic model configurations for Microindentation, Macro-Vickers, Multi-Vickers, Brinell or Rockwell type .

Displays test conditions and test results. By entering the specimen thickness and the presumed hardness, you can set a test force that satisfies the JIS conditions. Used for selecting a conversion scale, entering a setting for Pass/Fail determination, and specifying external output. In addition to the test force dwell time, you can specifyAll hardness testing methods lie under these categories. In this article, we will discuss hardness types, advantages, disadvantages, and applications. These things are important to understand as they have many consequences on the mechanism of indentation in the hardness testing methods. . Micro-indentation Tests. Micro Vickers and Knoop . ISO/TS 19278: 2019, Plastics Instrumented micro-indentation test for hardness measurement. Shimadzu Corporation Application News: “Hardness Test of Plastic Materials” 2019 Shimadzu Corporation Application News: “Evaluation of UV-degraded Plastics by FTIR and Dynamic Ultra Micro Hardness Tester” R. Fuji and C. Oya 2021In microindentation testing, hardness and elastic modulus are two fundamental properties that are accurately measured by pressing a sharp indenter into a surface of a material. Hardness is derived from the material’s resistance to permanent deformation under the indenter’s load, and is an important indication of the material’s ability to .

Standards Related to Microindentation Hardness Testing A considerable number of international standards for con ducting microindentation hardness testing exist. Most are found in three sources: DIN (W. German), ISO, and ASTM. The DIN standards for Vickers and Knoop test ing are 50133 and 52333, respectively. The ISO lists threeQualitest range of Micro Hardness Testers redefine precision and efficiency. With integrated designs, touch screen controls, and CCD image acquisition, the Micro Hardness Testers range from Qualitest ensures accurate measurements. For enhanced automation, these Hardness Testers feature fully or semi-automatic functionalities, setting a new standard in efficiency with .

It is desirable to begin by reviewing the development and the present state of hardness testing under low load, and to say something about the terminology. As the concept of micro-indentation hardness testing has not yet become commonly accepted, nor has any definition of it been universally agreed upon, it is desirable to begin by reviewing the development and the present .Supports a Wide Range of Testing Methods Record the relationship between the test force and the indentation depth. Test both the unload and load processes. Use the DUH-211S to perform cyclic load-unload tests and step load-unload tests. Supports Vickers Hardness Test function to measure the length of diagonals is provided as a standard feature.The CSM Micro Indentation Tester (Micro Hardness Tester: MHT) has been used for a very wide range of applications. It represents a very efficient automated method of determining the hardness and elastic modulus values on precise positions on .The Micro Hardness Tester takes center stage when it comes to examining the hardness of materials at a smaller sample, thin specimens, plated surfaces or coatings. With its precision and accuracy, this powerful instrument provides invaluable insights into a material's resistance to deformation, wear, and indentation.

abcam p24 elisa kit

micro indentation hardness

instrumented indentation hardness

hardness test for indentation

Il y a lasure et lasure. D'excellentes marques existent, il suffit d'y mettre le prix... Une lasure hélas se ravive, on n'y échappe pas au bout de quelques années.

micro indentation hardness tester|micro indentation hardness